10 Best Practices to Ensure Strong Pipeline Integrity Management

Outdated safety measures and a reactive approach to pipeline integrity management can cause severe infrastructure and environmental damage, disrupting oil and gas transportation and putting your company’s future at risk. And this is the reason why oil and gas pipeline companies should seek better pipeline integrity management practices and follow all strategies to implement it successfully. Pipeline integrity management is the bone of the oil and gas industry. Pipeline safety ensures better resource transportation and reduces chances of environmental risks.

15% of pipeline incidents are caused by operational errors. Mistakes should be identified before they cause damage, and companies should follow effective practices to avoid mishaps. Such strategies help companies reduce risk and protect the environment.

Best Pipeline Integrity Management Practices

Whether you’re an operator or an oil and gas pipeline company, applying these strategies will strengthen your pipeline systems and keep your operations running smoothly.

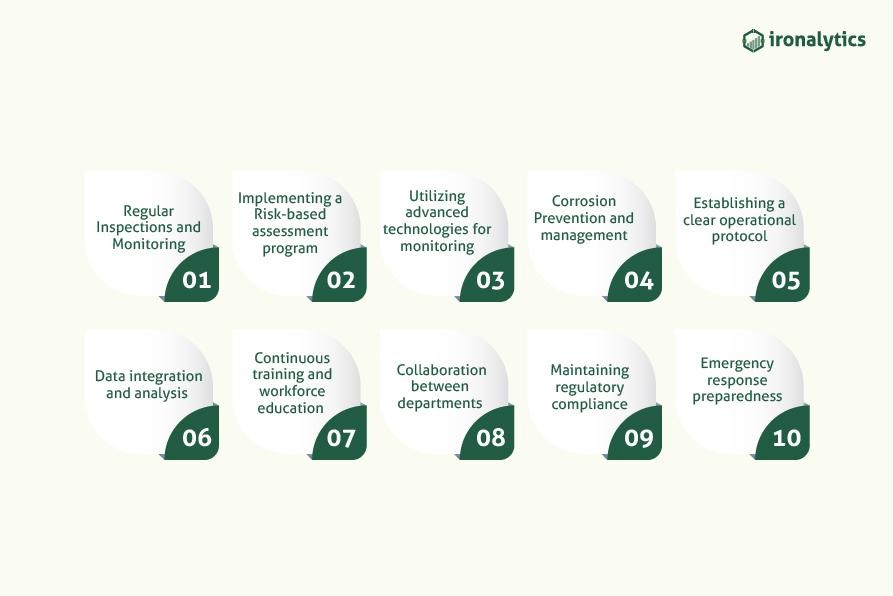

Here are the ten best practices which we will discuss in detail: 1. Regular Inspections and Monitoring 2. Implementing a Risk-based assessment program 3. Utilizing advanced technologies for monitoring 4. Corrosion Prevention and management 5. Establishing a clear operational protocol 6. Data integration and analysis 7. Continuous training and workforce education 8. Collaboration between departments 9. Maintaining regulatory compliance 10. Emergency response preparedness

Regular Inspections and Monitoring

Pipeline integrity management ensures the safety and lifecycle of pipeline systems. Regular inspections save your pipelines from preventing leakages, corrosions, and other risks, avoiding costly repairs and environmental hazards. 1. Importance of Inspections: Regular checks detect issues early, meet regulatory standards, and protect communities and the environment. 2. Technologies for Inspections: Tools like drones, ground sensors, and smart pigs provide real-time data, helping address vulnerabilities. 3. Inspection Frequency: Schedules depend on pipeline age and condition. Older pipelines need more frequent checks, while newer ones require fewer. Risk assessments determine the optimal frequency.

Implementing a Risk-Based Assessment Program

Risk-based assessment programs allow you to focus on the areas that require the most attention. By regularly assessing risks, you can prioritize sections of the pipeline that are more prone to failure, enhancing safety and reducing maintenance costs. Key factors to consider in your assessments include: ● Geographical Risks ● Material Used ● Pipeline Age

Utilizing Advanced Technologies for Monitoring

AI and IoT technologies are used in pipeline integrity management practices for monitoring the operations effectively and help in identifying key areas for improvement. They carry out operations which are usually critical in nature if done manually. 1. Real-Time Data Collection: IoT sensors monitor pipeline conditions in real time, detecting anomalies such as pressure drops or unusual flow patterns, which may signal leaks or blockages. This allows operators to respond quickly and prevent escalation. 2. Benefits of Predictive Analytics: AI-powered predictive analytics forecast failures, enabling proactive maintenance. By addressing issues before they occur, operators minimize disruptions, reduce maintenance costs, and extend pipeline lifespan, ensuring greater safety and reliability.

Corrosion Prevention and Management

Corrosion is a major cause of pipeline failure. Detecting and preventing these corrosions at its initial stage is crucial to avoid any kind of damage, which can cost a lot. Prevention methods focus on maintaining optimal environmental conditions, controlling moisture, and using inhibitors to reduce chemical reactions. Mitigating Corrosion Risks: 1. Coatings: Protective coatings shield pipelines from corrosive substances, significantly extending their lifespan. 2. Cathodic Protection: This electrochemical method prevents corrosion by making the pipeline a cathode, which is ideal for underground pipelines. 3. Material Upgrades: Corrosion-resistant materials like stainless steel or special alloys reduce degradation, especially in high-risk areas.

Establishing Clear Operational Protocols

Clear operational guidelines are key to safe and efficient pipeline management. These ensure everyone knows their roles in daily tasks and emergencies, reducing risks and maintaining compliance. 1. Staff Training: Regular training on safety, equipment use, and emergency procedures is essential. Well-trained employees can identify risks early and respond quickly. 2. Updating Protocols: Guidelines should be regularly updated with new technologies and regulatory changes. This ensures pipelines run smoothly and safely while staying up-to-date with advancements.

Data Integration and Analysis

Data integration and analysis help by combining information from various sources, such as inspections, monitoring systems, and historical records, into a unified platform. This enables teams to make better, faster decisions and spot potential issues early. ● Centralizing Inspection and Monitoring Data Effective pipeline management relies on gathering and centralizing data from inspections, real-time monitoring, and past performance. This provides a complete view of the pipeline's health, making it easier to access information, make informed decisions, and plan ahead. ● Spotting Trends with AI Tools AI and machine learning analyze data to identify patterns and risks, such as pressure fluctuations or temperature changes that could signal potential issues. Early detection allows operators to act before problems worsen, improving safety. ● Enhancing Decisions with Integrated Data Integrated platforms streamline data sharing across teams, offering real-time insights. This boosts decision-making, optimizes resource allocation, and improves safety and efficiency.

Continuous Training and Workforce Education

1. Keeping Technicians and Engineers Up-to-Date Ongoing training is key to helping technicians and engineers stay ready for the complexities of pipeline management. As technology and safety standards evolve, it's important for teams to stay current. Regular training ensures they can use advanced tools, follow updated safety guidelines, and maintain pipelines efficiently, directly supporting overall integrity. 2. Staying Updated on Technology and Compliance The pipeline industry constantly updates its regulations and technology. Teams need to stay informed to avoid penalties, ensure safety, and adopt best practices. By learning about the latest tools, like drones and smart sensors, employees can monitor pipelines more accurately and make timely risk assessments. 3. Cross-Functional Training for a Holistic Approach Cross-functional training gives teams a broader view of pipeline management, encouraging collaboration and problem-solving from multiple angles. By learning various aspects like inspection, maintenance, and data analysis, staff become more flexible and effective at addressing challenges.

Collaboration Between Departments

How Communication Between Operations, Engineering, and Management Improves Workflows Effective communication between operations, engineering, and management is key to keeping pipelines running smoothly. Clear communication reduces misunderstandings, speeds up decisions, and ensures that information on inspections, maintenance, and risks is quickly shared. This alignment ensures everyone works toward the same goals with the latest information, helping maintain pipeline integrity. Encouraging Cross-Functional Teams for Integrity Initiatives Cross-functional teams, combining expertise from different departments, offer comprehensive solutions to pipeline integrity issues. Engineers can focus on technical fixes while operations ensure they're feasible in the field. This teamwork leads to better, more practical solutions and strengthens overall pipeline management.

Maintaining Regulatory Compliance

Following and maintaining both national and international regulations is dynamic in nature. You should stay alert and flexible as the standards change. Regular audits, inspections, and staying ahead of regulatory updates are essential for ensuring compliance and keeping operations running smoothly without interruptions. ● Follow national and international safety, environmental, and operational regulations. ● Conduct regular audits and inspections to identify and fix compliance gaps. ● Adapt compliance strategies based on changing regulations and industry advancements. ● Maintain thorough documentation to prove adherence and avoid legal risks.

Emergency Response Preparedness

A solid emergency response plan is critical for reducing damage during pipeline incidents such as leaks, ruptures, or natural disasters. The plan should clearly outline the steps to take, including shutting down affected sections, notifying authorities, and ensuring the safety of personnel and nearby communities. A well-designed plan helps speed up response times, minimizes impact, and protects the environment. Here are the key points: ● Clear Procedures: The plan should provide clear steps for shutting down pipeline sections and notifying relevant authorities. ● Employee Training: Regular training and emergency drills are essential to ensure employees are prepared to act quickly in real scenarios, while also identifying any areas for improvement. ● Plan Updates: The emergency response plan should be regularly updated to reflect new risks and lessons learned, ensuring it remains effective and relevant in maintaining pipeline safety. Following these practices will protect your pipeline infrastructure safety from mishappenings. Most of these practices can be done manually but would that be effective when you can digitalize your pipeline operations? Or simple words, when you can assign someone expert in reading critical pipeline data, monitor them, and analyse it to understand where you need to improve? Yes, you are thinking right! Having extra help from such great resources will ensure your pipeline integrity management, which is Ironlytics.

Pipeline Integrity Management Solution: Ironlytics

Ironalytics is a robust platform designed to simplify pipeline integrity management for industries facing complex data and operational challenges. Its primary goal is to enhance safety and efficiency by automating data integration and threat analysis, covering areas such as cracks, dents, corrosion, cathodic protection, and right-of-use (ROU) issues. Key Features of Ironalytics: ● Pipeline Integrity Digitalization: Ironalytics consolidates data from multiple sources, providing clear insights into pipeline health. With custom dashboards, geotagging, and automated integrity KPIs, monitoring and reporting become effortless and accessible from any device. ● ROU/Integrity Management: The platform tracks ROU events like encroachments or third-party activities, ensuring legal compliance and reducing downtime. Integrated with drone surveillance, it offers real-time tracking and alerts for efficient management. ● Defect Assessments and ILI Analysis: Ironalytics automates in-line inspection (ILI) assessments, delivering detailed visualizations based on industry standards. It predicts corrosion, metal loss, and remaining pipeline life, enabling proactive maintenance. ● Geospatial Analysis: Leveraging Google Maps, Ironalytics provides geospatial visualizations of pipelines, showing asset locations, risk zones, and historical anomalies for informed decision-making. ● Risk Management: The platform automates threat detection and creates risk profiles, complying with ASME and API standards. This helps operators pinpoint high-risk areas and take preventative measures. ● SCADA Integration: Ironalytics integrates with SCADA systems for real-time analysis of product quality and internal corrosion modeling, predicting maintenance needs and extending pipeline lifespan.

Conclusion

Ensuring pipeline integrity and adhering to safety standards in the oil and gas industry presents significant challenges for companies, making it difficult to implement and sustain these practices effectively. Platforms like Ironalytics provide essential digital solutions that streamline pipeline management, ensuring real-time monitoring and proactive maintenance to maintain integrity and operational excellence in the oil and gas industry. Book a demo with Ironalytics today to discover how our platform can help you.