7 Key Data Integration Challenges in the Pipeline Industry Explained

Data integration and management in the oil and gas pipeline industry face significant challenges due to their complex, multi-layered operations. Lack of data integration leads to several issues, slowing down pipeline companies' operational efficiency. As operations scale, managing and processing vast amounts of data in real-time becomes increasingly difficult, which can impact the timely identification of potential risks, such as leaks, corrosion, or pressure anomalies. These challenges highlight the need for more sophisticated solutions to streamline data integration and management for improved pipeline integrity and operational efficiency. Here are the top seven challenges in Data integration and Management in Pipeline Companies which we are going to discuss:

1. Data silos across multiple systems in oil and gas 2. Inconsistent data formats 3. Real-time data integration 4. Data security and compliance 5. Legacy systems and outdated infrastructure 6. Lack of standardisation in data management 7. Scaling Integration Efforts

Data Silos Across Multiple Systems in Oil and Gas

Pipeline Companies usually rely on different software and systems to perform and manage certain operations. Systems like ERP, SCADA, and other legacy systems are used. However, each of them works independently and in an isolated mode, creating data silos. Data silos in industries like oil and gas pipelines can create different data integration and management challenges: 1. Sharing and Accessing Pipeline Data: Gathering and sharing information from different departments using different software will be difficult. For instance, an operations team relying on SCADA for real-time monitoring may struggle to collaborate with the financial department using ERP software, leading to cumbersome data-sharing processes. 2. Inconsistent Data Formats: Different systems used in pipeline companies present data in different formats, which can cause inconsistency in all pipeline data. This can make it challenging to analyse multiple data sets to get a cohesive picture of operational performance.

Inconsistent Data Formats

Pipeline companies manage various data types, from sensor-generated operational data to financial reports. These data types often come in different formats, creating significant data integration and management challenges. 1. Incompatibility: For instance, sensor data from SCADA systems might be stored in a format that is not directly compatible with financial data from an ERP system, requiring manual intervention to reconcile differences. 2. Manual Data Cleaning: Because of this incompatibility, companies often perform manual data cleaning and transformation to ensure that data from different sources can be effectively integrated. This manual process is time-consuming and labour-intensive, increasing operational costs. 3. High Labour Costs: The manual process increases labour costs and slower turnaround times when utilising data for operational insights, which can reduce overall efficiency and competitiveness in a fast-paced industry.

Real-Time Data Integration

Monitoring Pipeline operation and performance is important to avoid accidents and check overall efficiency. For this, real-time data integration is crucial. Pipeline companies need real-time data to monitor and detect any kind of risks to pipeline integrity and safety. However, the process of getting real-time pipeline data comes with its challenges in data integration and management. 1. Handling High-velocity data: Pipeline data generated by sensors needs to be processed quickly to ensure safe and consistent pipeline operations. Additionally, maintaining low latency is important for real-time data analytics and decision-making. Any delay in processing data can result in missed or late detection of issues like leaks or pressure drops. 2. Operational downtime: Delays in real-time data integration can have a severe impact. Failure to quickly detect and respond to pipeline anomalies can lead to safety risks and financial losses due to necessary repairs, environmental damage, or regulatory fines.

Data Security and Compliance

In pipeline companies, data is constantly exchanged for different operational performance and analysis. While data is exchanged, data security becomes important to protect it from cyber-attacks and maintain compliance with industry regulations. Protecting crucial data like financial information in the pipeline is also important for operational integrity. However, many challenges during this process affect data integration and management in the company. 1. Securing Data Transfer: During system integrations data moves between different platforms such as SCADA, ERP, and legacy systems, it becomes vulnerable to cyber threats like unauthorised access and ransomware. To mitigate these risks, companies must employ strong encryption and security measures. 2. Data Privacy Laws: Adhering to data privacy laws like GDPR and industry standards such as ISO adds complexity. Non-compliance can lead to hefty regulatory fines and damage a company’s credibility. The impact of weak data security practices can be severe, including data breaches, financial losses, and a loss of stakeholder trust.

Legacy Systems and Outdated Infrastructure

Many oil and gas companies still rely on legacy systems that are not designed for modern data integration. These systems are typically rigid and outdated, creating significant challenges when integrating them with modern cloud platforms and applications. 1. Flexibility: Legacy systems often need more flexibility to connect seamlessly with newer technologies, making it difficult to access real-time data and leverage advanced analytics. 2. High replacement cost: Upgrading or replacing this older infrastructure is costly and complex. The systems are deeply embedded in operational workflows, meaning that any transition to more modern alternatives requires substantial financial investment, time, and expertise. 3. Incompatible: The impact of these challenges is that legacy systems often need to be more compatible with modern platforms, leading to inefficient data integration. This results in operational delays, higher maintenance costs, and an inability to fully leverage the benefits of modern data-driven technologies.

Lack of Standardization in Data Management

The absence of industry-wide data standards in the pipeline companies creates significant difficulties in integrating data from multiple sources, such as stakeholders, vendors, and operational units. 1. Standardisation: Different organisations often use disparate naming conventions, metadata formats, and data models, which makes it challenging to combine and standardise the information. 2. Data accuracy and consistency: Integrating data in various formats can make the process difficult. Inconsistencies in data collection methods and labelling can introduce errors, making the information unreliable when used in centralised systems for analysis. 3. Poor Data Quality: The impact of this lack of standardisation is poor data quality, which can lead to errors in analysis. These errors may result in costly mistakes in decision-making, such as misjudging operational efficiency or making flawed maintenance investments.

Scaling Integration Efforts

As oil and gas operations expand, integrating data from multiple sources, systems, and processes becomes more complex. This growth brings several challenges. 1. Managing Data Integration: For global operations become difficult due to varying regulatory and operational requirements in different regions. 2. Speed or accuracy: As the volume of data grows with the scaling of operations, handling increased data volume without compromising speed or accuracy becomes a major challenge. 3. Real-time data processing: It is critical for operational efficiency and decision-making, can slow down, and data accuracy may suffer if proper infrastructure isn't in place to manage the expanded load.

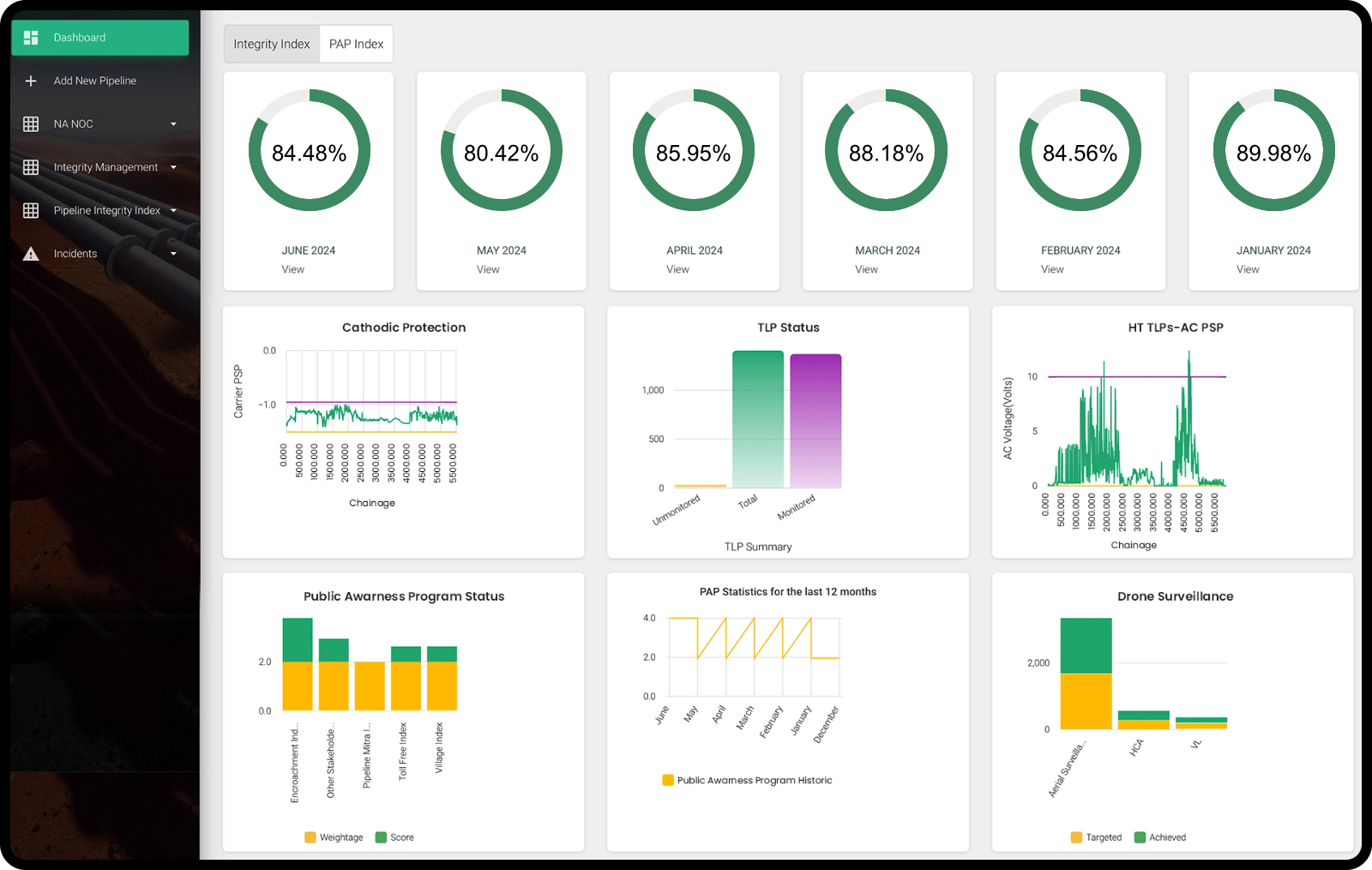

Pipeline Data Integrity Management Solution: Ironalytics

Ironalytics is an all-in-one platform designed to optimise pipeline integrity management for industries facing complex data and operational challenges. It focuses on improving safety and efficiency by automating data integration and threat analysis, addressing key issues such as cracks, dents, corrosion, cathodic protection, and right-of-way (ROW) management. Key Features of Ironalytics: ● Pipeline Integrity Digitalization: Ironalytics consolidates data from multiple sources, offering clear, actionable insights into pipeline health. Its customisable dashboards, geotagging features, and automated integrity KPIs simplify monitoring and reporting and are accessible from any device. ● ROW/Integrity Management: The platform tracks right-of-way (ROW) activities like encroachments or third-party interventions, ensuring legal compliance and reducing downtime. Integrated with drone surveillance, it provides real-time tracking and alerts for efficient management. ● Defect Assessments and ILI Analysis: Ironalytics automates in-line inspection (ILI) assessments, providing detailed visualisations based on industry standards. It predicts corrosion, metal loss, and the remaining pipeline lifespan, allowing for proactive maintenance planning. ● Geospatial Analysis: Leveraging Google Maps, the platform offers geospatial visualisations of pipelines, showing asset locations, risk areas, and historical anomalies to support informed decision-making. ● Risk Management: The platform automates threat detection and builds risk profiles in line with ASME and API standards, enabling operators to identify high-risk zones and implement preventive measures. ● SCADA Integration: Ironalytics integrates with SCADA systems, offering real-time product quality analysis and internal corrosion modelling, which helps predict maintenance needs and extend pipeline lifespans.

Conclusion

Effectively managing pipeline integrity is crucial for avoiding costly repairs, environmental hazards, and operational inefficiencies in the oil and gas industry. Data silos across multiple systems like ERP, SCADA, and legacy platforms create challenges in data integration, making it difficult to achieve seamless collaboration and real-time monitoring. This is where a Pipeline Integrity Management System (PIMS) like Ironalytics becomes invaluable. Ironalytics simplifies pipeline management by centralising data from various systems, automating threat detection, and integrating geospatial analysis and SCADA systems. Book a demo today to explore how Ironalytics can safeguard your pipeline infrastructure.