Why is Pipeline Integrity Management Crucial in the Oil & Gas Industry

Maintaining strong pipeline integrity management is at the core of the oil and gas industry, where smooth and reliable pipeline operations depend on the safe transport of resources. Managing data for a pipeline, which spans long distances as a linear asset, creates a tedious task for operators. The complexity and high risks of the industry mean that even minor issues in pipeline systems escalate quickly into major environmental hazards and operational disruptions. Operators must actively manage and monitor pipelines to ensure safety, prevent accidents, and optimize operational efficiency in the oil and gas sector. In simple words, maintaining a pipeline's integrity means ensuring it stays in good condition and doesn't develop issues. Operators first collect data from different places to look for rust, cracks, or weak spots. Once they have this information, they assess the risks—figuring out if anything could go wrong. After identifying potential problems, they take action to prevent them and then put together reports to track everything. It's all about keeping the pipeline safe and working efficiently.

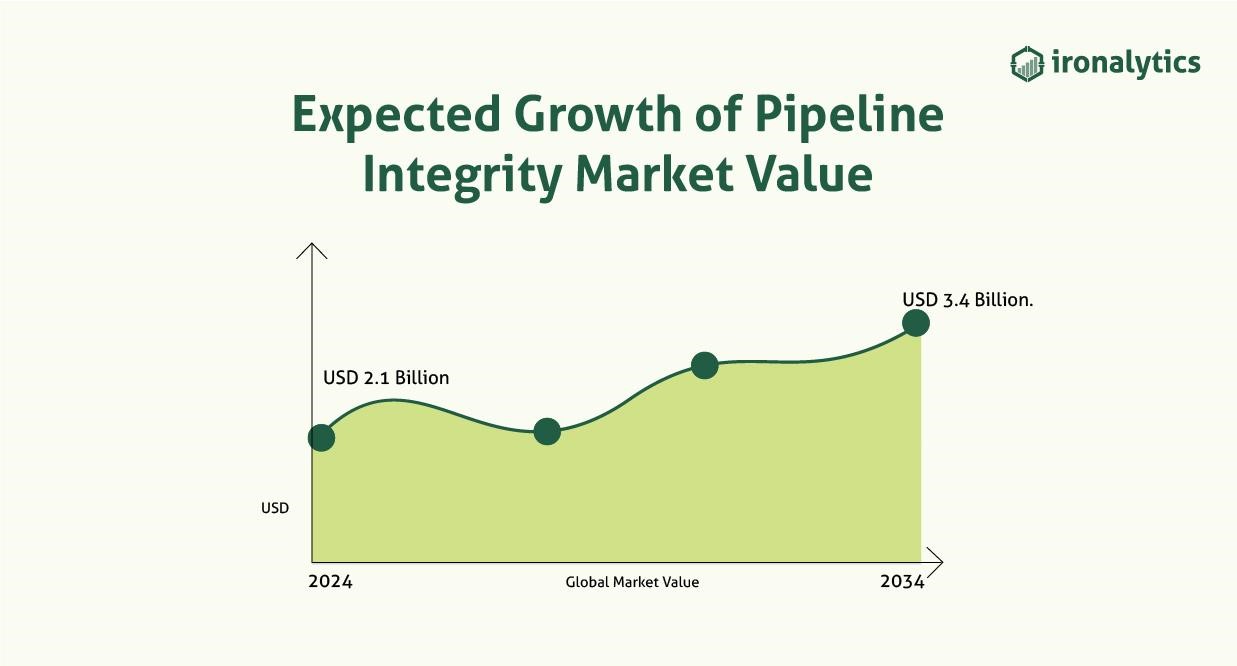

The global pipeline integrity market is valued at USD 2.1 billion and is projected to reach USD 3.4 billion by 2034. This growth underscores companies' emphasis on effective pipeline integrity management to ensure safety, efficiency, and regulatory compliance. But imagine performing those operations without a systematic approach—it's a long and tedious process, often taking days or months to complete. And here's the genuine concern: the risk of errors. Human mistakes are common. However, even the slightest mistake can cause dangerous consequences regarding pipeline integrity.

Pipeline Integrity Management: Definition & Key Components

Pipeline integrity management keeps pipelines safe, reliable, and running smoothly. However, it involves complex operations, such as actively monitoring, inspecting, tracking, and maintaining pipelines to catch any issues before they become more significant problems. By monitoring potential risks like leaks or failures, you can address them early and keep your pipeline network operating efficiently. Such measures help prevent environmental damage and ensure everything stays in line with regulations, protecting your infrastructure and the people who depend on it.

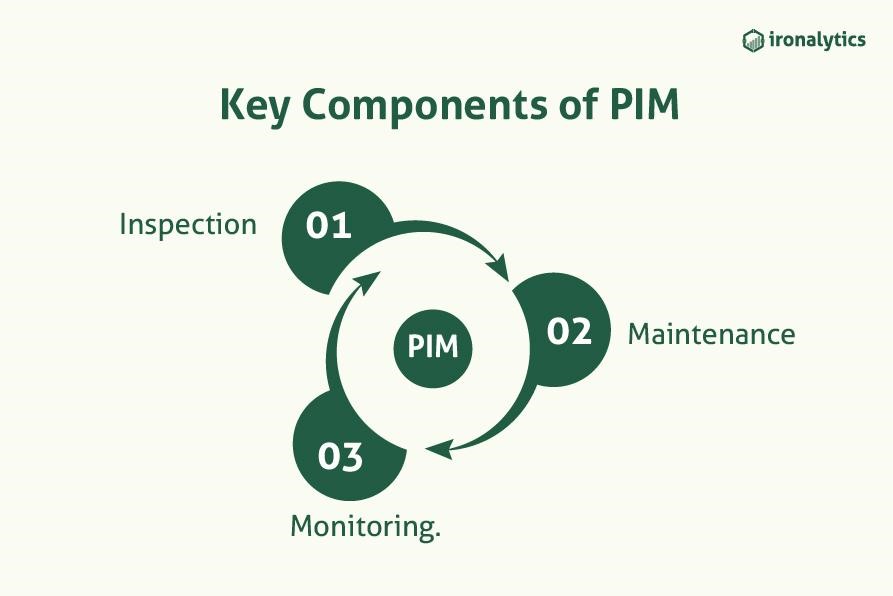

Key Components of PIM

Any pipeline integrity management has three major components or three crucial activities: inspection, maintenance, and monitoring. 1. Inspection: Regular inspections, including internal and external evaluations, use tools like in-line inspection devices (smart pigs), drones, and sensors. These inspections help detect issues such as corrosion, cracks, or physical damage in the pipeline. 2. Maintenance: Maintenance involves both preventive and corrective actions to address potential or existing pipeline issues. It includes repairing damages, cleaning pipelines, and applying protective measures to prevent further degradation. 3. Monitoring: Continuous monitoring systems track real-time data such as pressure, flow, and temperature. This helps operators quickly detect anomalies or signs of pipeline failure, enabling swift action to prevent more significant issues.

Importance of Pipeline Integrity Management

Pipelines are critical assets in the oil and gas industries. They transport different resources safely and efficiently. So, maintaining healthy pipeline integrity prevents companies from avoiding risks like leaks, ruptures, and explosions. Sometimes, it can also cause severe accidents and natural disasters. This becomes even more critical when you consider that pipelines often run through densely populated areas or near crucial infrastructure. Any issue here isn't just about property damage—it could put people's lives at risk. Regarding environmental safety, ecological fallout from oil or gas spills is possible if you miss any pipeline leaks. It is essential to ensure that while carrying such critical resources via pipelines, you provide your overall pipeline integrity. From an operational standpoint, a well-maintained pipeline keeps everything running smoothly, ensuring no costly delays or interruptions in the supply chain. Monitoring and maintenance can significantly reduce repair costs and extend the pipeline's lifespan, which means a better return on investment. Regular integrity checks also ensure that companies meet industry standards, helping them avoid fines, shutdowns, or other legal headaches that could damage their reputation and bottom line.

Key reasons why pipeline integrity management is essential: ● Safety: Maintaining pipeline integrity prevents leaks, ruptures, and explosions, minimizing risks to human lives and property. ● Environmental Protection: Helps avoid oil and gas spills, protects ecosystems, and ensures regulatory compliance. ● Operational Efficiency: Maintains uninterrupted supply chains, reduces maintenance costs, and extends asset lifespan. ● Economic Impact: Lowers repair and downtime costs and increases return on investment. ● Regulatory Compliance: Ensures adherence to industry safety standards, avoiding fines and shutdowns.

Pipeline Integrity Management Challenges

Physical Damage

The crucial challenge for any oil and gas company is to prevent pipelines from sustaining physical damage or corrosion. Physical damages can occur due to environmental and external factors. When pipelines are exposed to moisture, the surroundings' temperature changes, causing chemical reactions that cause damage, such as internal and external corrosion. This weakens the pipeline walls and increases the chances of leaks. External forces, such as heavy machinery or construction activities, cause cracks and physical damage. Safeguarding pipelines from these physical damages is always challenging for companies.

Older Infrastructure

The pipeline we are using today was installed decades ago. Such pipelines become weaker with time and are more prone to failure. They also do not meet modern safety and durability standards, making them vulnerable to leaks and environmental harm. As these systems age, maintenance costs and complexity increase significantly. It's a growing challenge for companies to balance the need for safe operations with the expenses of upgrading or replacing outdated infrastructure.

Geographical and External Threats

Pipelines exist in deserts, mountains, and underwater, but maintaining and monitoring them is more complex than keeping them in plains. Finding and fixing problems in remote or underwater pipelines is expensive and technically challenging. Unexpected dangers like earthquakes, floods, or landslides can seriously damage pipelines. Human activities, like unauthorized building, vandalism, or accidental digging near pipelines, also add to the challenge of keeping them safe and working correctly.

Emerging Technologies in Pipeline Integrity Management

Many new and innovative technologies have been used to monitor, inspect, and maintain pipelines. IoT, AI, drones, and robotics are transforming real-time monitoring, vulnerability detection, and pipeline inspections for enhanced safety and efficiency.

Key Technologies in Pipeline Integrity Management:

1. Sensors and IoT

Sensors in pipeline monitoring measure key parameters like pressure, flow, temperature, and corrosion to detect anomalies such as leaks or blockages. IoT devices collect and transmit this data in real time, enabling remote monitoring and faster response to issues. This constant monitoring means potential issues, like leaks or pressure drops, get spotted early, allowing for quick fixes before they become more significant problems.

2. AI and Predictive Analytics

AI and predictive analytics collect pipeline data from sensors and IoT. This data is then processed using machine learning models, which analyze patterns and trends to predict potential issues such as leaks or structural failures. The system uses these insights to alert operators, enabling them to take preventive actions, optimize maintenance schedules, and ensure continuous, safe pipeline operations.

3. Drones and Robotics

Drones capture high-resolution images and thermal data of pipelines from outside, and robots conduct critical internal inspections. These tools can detect cracks or weaknesses in difficult-to-access areas, improving inspection accuracy and reducing the need for people to work in hazardous environments. Managing all these pipeline integrity management sounds hectic. So far, you have understood the importance of pipeline integrity management and how neglecting it can cause environmental risks. You need a proper systematic approach to maintain smooth pipeline integrity management and avoid risks. Effective software for maintaining pipeline integrity is available. One such reliable pipeline integrity management solution is Ironlytics.

Effective Pipeline Integrity Management System: Ironlytics

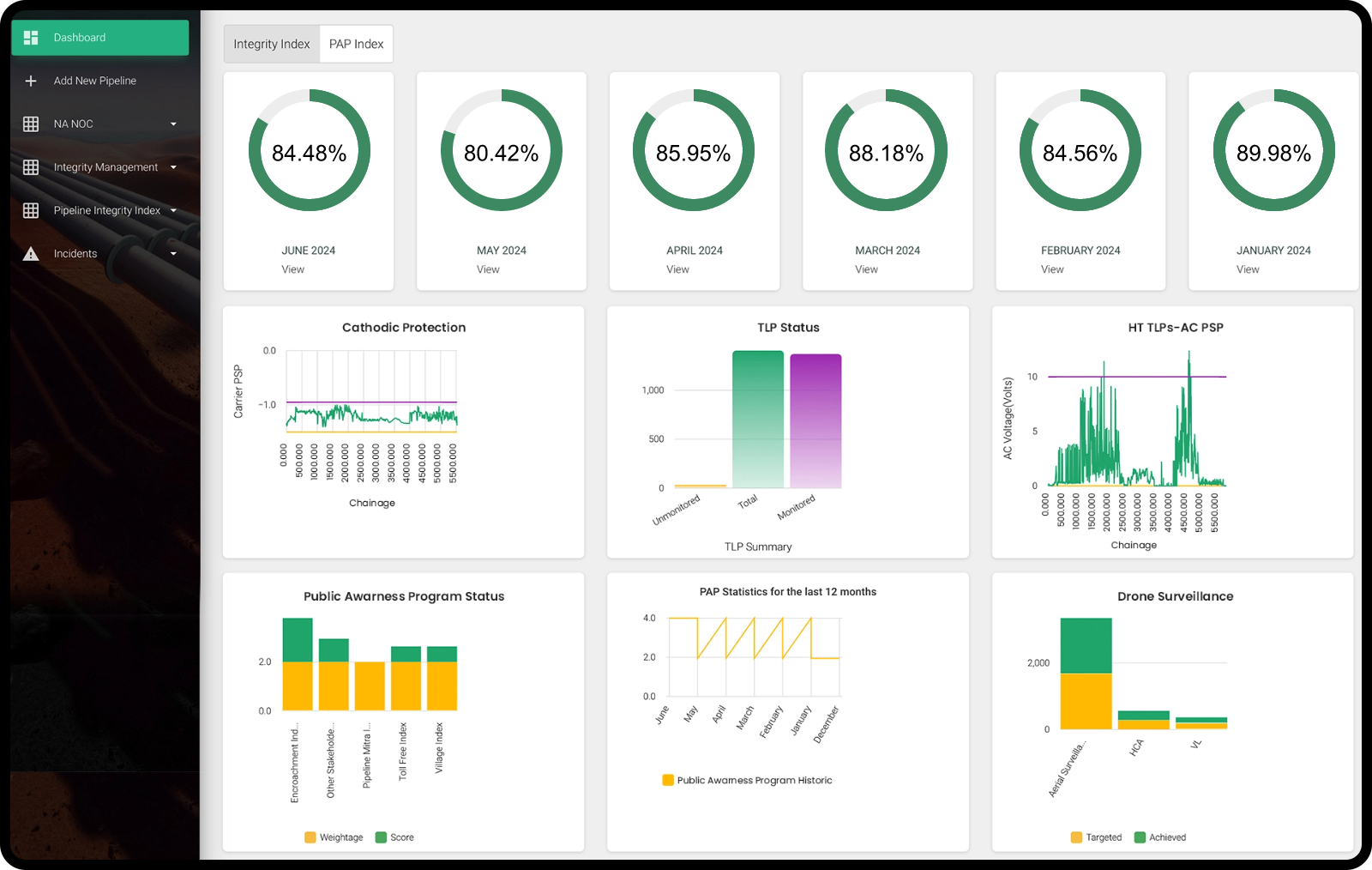

Ironalytics is a robust platform designed to streamline pipeline integrity management, particularly for industries managing complex data environments and operational challenges. Its primary aim is to enhance safety and operational efficiency by automating data integration and threat analysis across multiple domains, such as cracks, dents, corrosion, cathodic protection, and right-of-use (ROU) issues.

Key Features of Ironalytics:

1. Pipeline Integrity Digitalization: Ironalytics enables the seamless digitization of data from various sources, providing comprehensive insights into pipeline health. It integrates data through custom dashboards, geotagging, and the generation of automated integrity KPIs. This improves accessibility via multiple devices and simplifies monthly reporting and cathodic protection monitoring. 2. ROU/Integrity Management: The platform automatically tracks ROU events, such as encroachments or third-party activities, ensuring legal compliance and reduced downtime. This module is integrated with drone surveillance for real-time tracking and notice generation, creating an efficient management ecosystem. 3. Defect Assessments and ILI Analysis: Ironalytics facilitates automated in-line inspection (ILI) assessments, improving accuracy with customized visualizations and assessments based on industry standards. To support proactive maintenance, it predicts metal loss, dent severity, corrosion rates, and pipelines' remaining life. 4. Geospatial Analysis: Ironalytics offers geospatial visualizations of pipeline data using Google Maps, enhancing decision-making through a holistic view of pipeline conditions, including asset locations, risk zones, and historic anomalies. 5. Risk Management: With its risk assessment capabilities, Ironalytics adheres to guidelines such as ASME and API standards. It automates threat detection, generates risk profiles, and helps operators visualize high-consequence areas for proactive risk mitigation. 6. SCADA Integration: The platform integrates with SCADA systems to provide real-time product quality analysis and advanced internal corrosion modeling, utilizing algorithms to predict maintenance needs and pipeline longevity.

Conclusion

Pipeline integrity management is necessary for ensuring safety, environmental protection, and cost efficiency in the oil and gas industry. Maintaining their integrity is vital as pipelines face aging infrastructure and external threats. Emerging technologies like AI, IoT, and drones enhance PIM through real-time monitoring and predictive analytics, making it more efficient and reliable. Yet, specialized software is needed to carry out a few crucial operations for today's technology and safety measures. Ironlytics is an effective solution for managing pipeline integrity. Book a demo with Ironalytics today to discover how our platform can help you.